A welding helmet is a specialized piece of personal protective equipment designed to shield a welder’s face, eyes, and neck from the intense and potentially harmful light, heat, and sparks generated during welding processes. Welding is a common practice in various industries, including construction, manufacturing, and automotive repair, and it involves the use of high-temperature electric arcs or flames to join metals. The intense radiation and sparks produced in welding can cause serious eye and skin damage if not properly protected against.

Welding helmets are equipped with a darkened visor or lens, often made of auto-darkening material, which darkens when exposed to the bright welding arc but allows for clear vision when not welding. This auto-darkening feature ensures that the welder can maintain visibility of the workpiece without having to frequently lift or flip up the helmet, increasing efficiency and reducing the risk of eye strain.

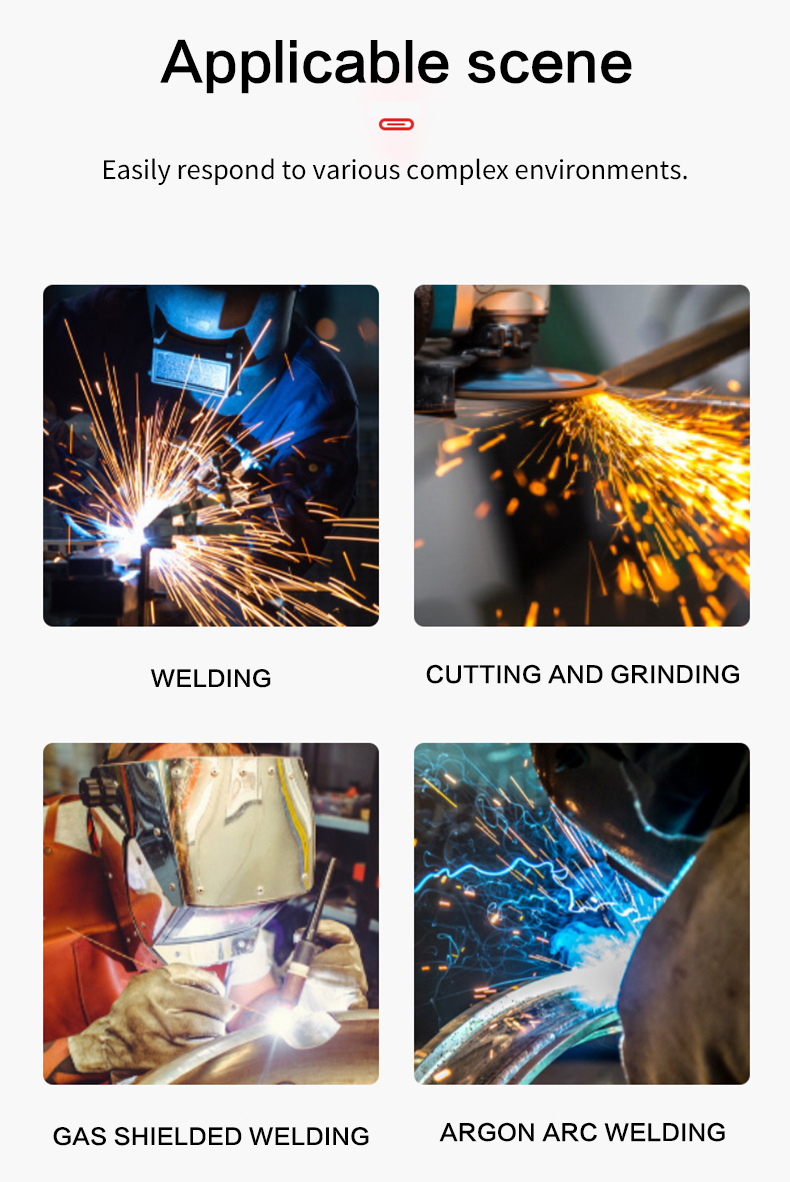

In addition to the auto-darkening visor, welding helmets typically feature a sturdy outer shell for physical protection, adjustable headgear for a comfortable and secure fit, and sometimes even additional features like respiratory protection or grinding shields. They come in various styles and designs to cater to different welding applications, ensuring that welders are adequately protected while working with various welding methods, from MIG and TIG welding to arc and oxy-fuel welding.

Welding helmets are a critical component of welders’ safety gear, offering protection against the hazardous elements involved in the welding process. Wearing a welding helmet is essential to safeguard the welder’s vision and overall well-being, making it an indispensable tool in the welding industry.